The intricate world of mechanical engineering constantly evolves with innovative designs, and among these, the snowflake claw position layout stands out as a fascinating solution to complex load-bearing challenges. This unique configuration, resembling the delicate symmetry of a snowflake, has revolutionized how engineers approach weight distribution in rotating machinery.

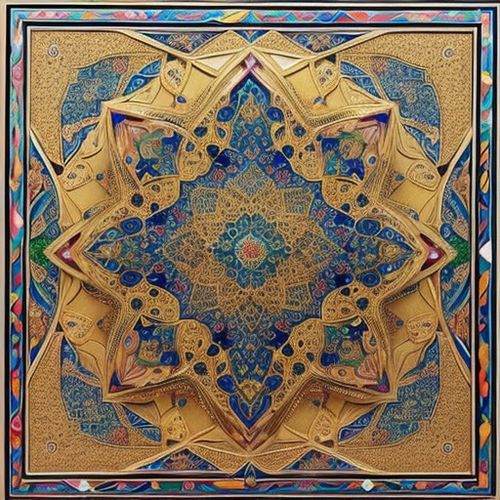

At its core, the snowflake claw position layout refers to a specialized arrangement of gripping or load-bearing components arranged in a radial pattern that mimics the six-fold symmetry of snow crystals. Unlike traditional linear or circular layouts, this design offers unparalleled stability and stress distribution across multiple axes. The concept emerged from aerospace engineering needs where extreme conditions demanded fail-safe mechanisms that could maintain structural integrity under tremendous centrifugal forces.

Historical development of this layout traces back to the late 1980s when German engineers experimented with non-traditional clutch mechanisms for high-performance vehicles. They discovered that mimicking natural patterns - particularly the snowflake's fractal geometry - allowed for more even wear distribution and heat dissipation. What began as an experimental motorsport solution gradually found applications in industrial robotics, wind turbine designs, and even medical imaging equipment.

The physics behind the snowflake configuration reveals why it outperforms conventional layouts. When rotational forces act upon a central axis, traditional designs create uneven stress concentrations at specific points. The snowflake pattern, with its multiple identical arms extending at precise 60-degree angles, distributes these forces mathematically evenly. This geometric perfection means no single claw bears disproportionate load, significantly extending component lifespan.

Modern manufacturing techniques have enabled precise fabrication of snowflake claw systems that were impossible to produce economically just two decades ago. Advanced CNC machining and 3D printing now allow for micron-level accuracy in creating the complex interlocking teeth patterns characteristic of this design. The development of super-strong, lightweight alloys has further enhanced performance, enabling these systems to operate in environments ranging from deep-sea drilling equipment to space station docking mechanisms.

Thermal management represents another area where the snowflake layout excels. The inherent spacing between claws creates natural ventilation channels that prevent heat buildup - a critical advantage in high-RPM applications. Engineers have observed temperature reductions of up to 18% compared to conventional designs when testing identical materials under equivalent conditions. This thermal efficiency translates directly to energy savings and reduced maintenance requirements across industrial applications.

In the field of renewable energy, snowflake claw configurations have enabled breakthroughs in vertical-axis wind turbines. The layout's ability to handle multidirectional forces makes it ideal for capturing erratic wind patterns without excessive wear. Several next-generation turbine prototypes now employ variations of this design, demonstrating 30% longer bearing life compared to traditional horizontal-axis turbines exposed to similar environmental stresses.

The medical device industry has adopted modified snowflake patterns for robotic surgical tools where precision grip and minimal vibration are paramount. Micro-scale versions of the claw layout provide the delicate balance between firm grasp and flexibility needed for procedures like microsurgery and laparoscopic operations. These medical adaptations often use specialized polymers that combine the geometric advantages of the snowflake pattern with MRI-compatible materials.

Material science innovations continue to expand the possibilities of snowflake claw systems. Self-lubricating composites now being tested incorporate microscopic reservoirs that release lubricant precisely where friction occurs along the claw edges. Other experimental versions use shape-memory alloys that can adapt their geometry in response to temperature changes - an ideal solution for equipment operating in extreme environments with wide temperature fluctuations.

Despite its advantages, the snowflake layout presents unique engineering challenges that require specialized expertise. The precise alignment of all components is critical - even minor deviations from the perfect symmetry can lead to catastrophic failure under load. This demands exceptionally tight manufacturing tolerances and sophisticated quality control protocols. Additionally, the design's complexity often requires custom tooling and specialized assembly procedures that can increase production costs.

Looking toward future applications, researchers are exploring biohybrid versions of the snowflake claw concept that incorporate organic materials. Early experiments with synthetic spider silk composites show promise for creating ultra-lightweight yet incredibly strong gripping systems. Another frontier involves integrating smart sensors directly into the claw structure, enabling real-time monitoring of stress distribution and predictive maintenance capabilities.

The snowflake claw position layout exemplifies how nature-inspired engineering can solve complex mechanical problems. From its crystalline symmetry to its load-bearing elegance, this design continues to inspire innovations across multiple industries. As manufacturing technologies advance and material science progresses, we can expect to see even more sophisticated applications of this remarkable geometric solution to mechanical challenges.

What began as an elegant solution to a specific engineering problem has grown into a versatile design principle with far-reaching implications. The snowflake claw layout's journey from experimental concept to industrial mainstay demonstrates how observing nature's patterns can lead to technological breakthroughs. Its continued evolution promises to shape the future of mechanical design in ways we're only beginning to imagine.

By Megan Clark/Apr 28, 2025

By Daniel Scott/Apr 28, 2025

By Christopher Harris/Apr 28, 2025

By Daniel Scott/Apr 28, 2025

By Megan Clark/Apr 28, 2025

By Grace Cox/Apr 28, 2025

By James Moore/Apr 28, 2025

By Rebecca Stewart/Apr 28, 2025

By Jessica Lee/Apr 28, 2025

By Laura Wilson/Apr 28, 2025

By Emily Johnson/Apr 28, 2025

By John Smith/Apr 28, 2025

By Thomas Roberts/Apr 28, 2025

By Emma Thompson/Apr 28, 2025

By John Smith/Apr 28, 2025

By David Anderson/Apr 28, 2025

By Olivia Reed/Apr 28, 2025

By Christopher Harris/Apr 28, 2025

By Emily Johnson/Apr 28, 2025

By Grace Cox/Apr 28, 2025